1.300L combined brewhouse system description:

Germany is famous at the beer and the beer equipment , the brewing technology is also unique, Cassman's Germany standard brew house is two vessels.One vessels is the steam heated mash and boiling, another is the combined Lauter and Whirlpool tank at the bottom .

The biggest advantage is the the system can accomplish the naturally Lauter.

All the tanks,pipelines,and valve are manufactured by SUS 304 , the brew kettle can be heated by steam, both the tanks are insulated on 80mm .

There are frequency agitators inside of the two tanks,rotary spray ball,360 degree glass manhole,sight glass,the motor,frequency transformer were installed by world famous brand. Also with hop filter, wort buffer tank,base and stand, and other necessary accessories.

Simply pipelines designed and equipped with SUS 304 plateheat exchanger ; the entire system is fully automated and uses pneumatic valves.

2.300L combined brewhouse system*3 vessels parameters:

Mash tun / boiling kettle tank:

• Capacity:300L +25% head space(minimum)

• Interior Shell:SUS304 Stainless Steel,thickness: 3.0mm;

• Exterior Shell:SUS304 Stainless Steel,thickness: 2.0mm;

• 100% TIG welding with pure argon gas shield

• Interior Finish: polished

• Insulation:Polyurethane-thickness:80mm.

• Heating: steam jacket for side of the tank, 50cm height.

• Steam inlet valve controlled by control system

• With steam condenser

• Grain rake with motor and turbine reducer, Power: 0.75KW

• LED sight light with battery

• Level gauge

• Full size glass top mounted man way

• 360°coverage CIP spraying ball with 2 pieces

• PT100 temperature sensor

• Adjustable support legs 4 pieces.

Lauter tun:

• Capacity:300L +25% head space(minimum)

• Interior Shell:SUS304 Stainless Steel,thickness: 3.0mm;

• Exterior Shell:SUS304 Stainless Steel,thickness: 2.0mm;

• 100% TIG welding with pure argon gas shield

• Interior Finish: polished

• Insulation:Polyurethane-thickness:80mm.

• Grain rake with motor and turbine reducer, Power: 0.75KW

• The motor with Frequency converter

• LED sight light with battery

• Full size glass top mounted man way

• Side mounted grain outdoor with grain chute

• Laser cutting V-wire False Bottom/Sieve plate,with handle

• False bottom support at the bottom of the tank

• Plate thickness:4mm, form:Strip-shaped holes

• Manually spent malt remove.

• 360°coverage CIP spraying ball with 2 pieces

• Easy clean and detachable sparging spray ring

• PT100 temperature sensor

Whirlpool tank:

• Capacity:300L +25% head space(minimum)

• Interior Shell:SUS304 Stainless Steel,thickness: 3.0mm;

• Exterior Shell:SUS304 Stainless Steel,thickness: 2.0mm;

• 100% TIG welding with pure argon gas shield

• Interior Finish: polished

• Insulation:Polyurethane-thickness:80mm.

• Heating way: side and bottom steam jacket

• With steam condenser

• LED sight light with battery

• Level gauge

• Full size glass top mounted man way

• 360°coverage CIP spraying ball with 2 pieces

• PT100 temperature sensor

• Adjustable support legs 4 pieces.

3.Combined brewhouse system reference drawings:

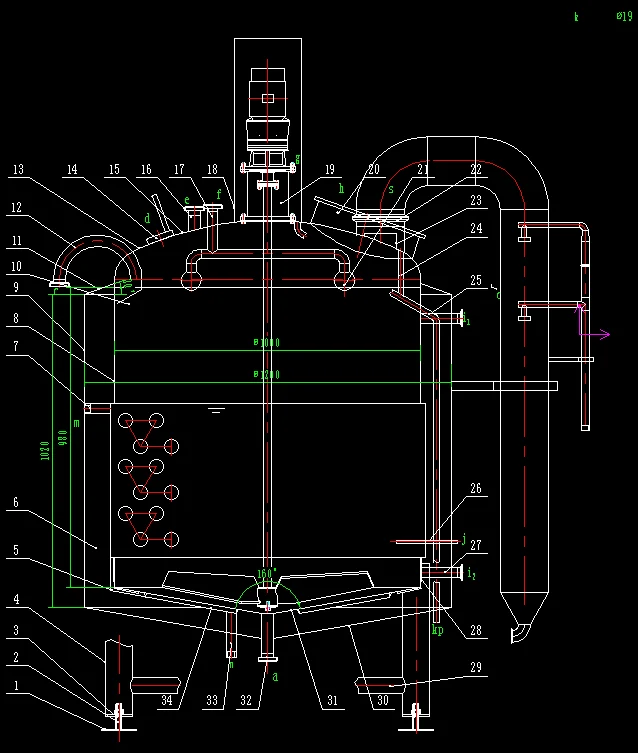

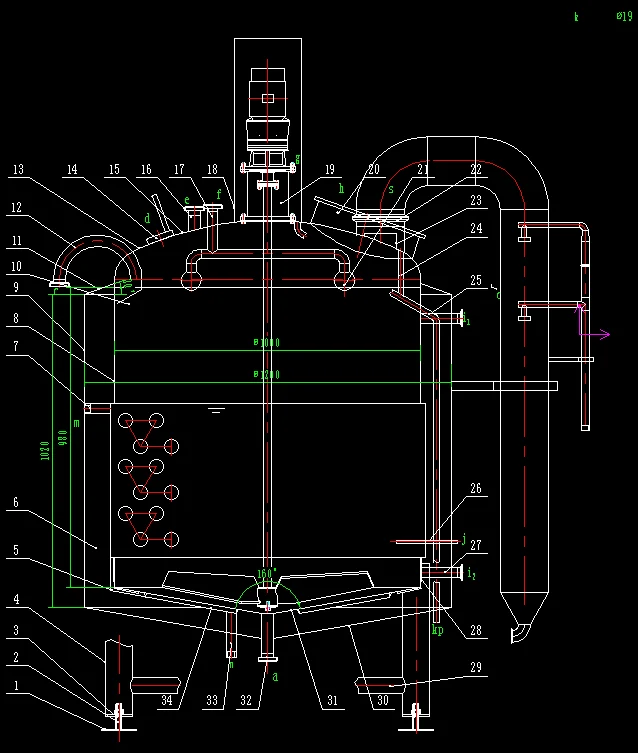

Mash/kettle tank drawing:

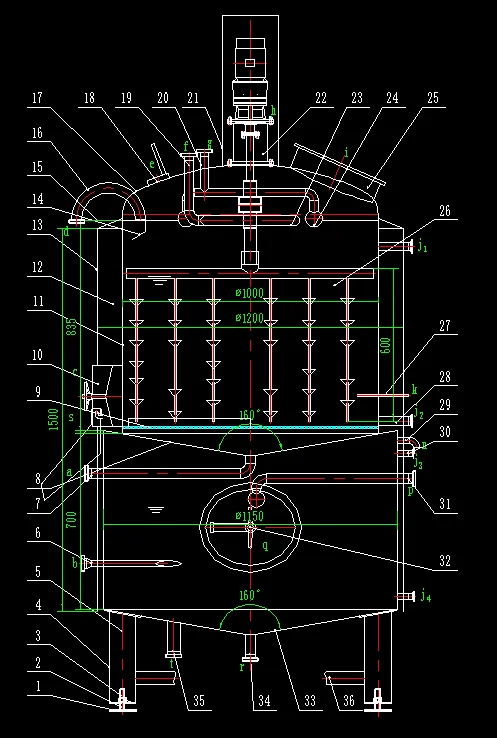

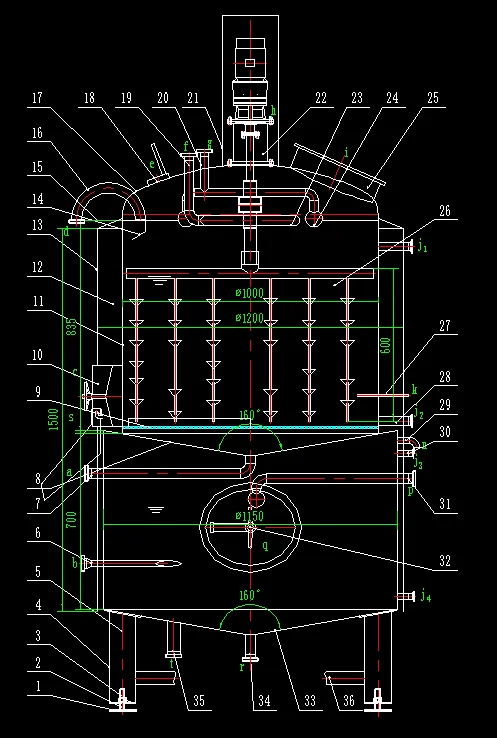

Lauter tun +whirlpool tank drawing:

4.Brewhouse system details:

English

English